Custom Plastic Trimming

Precision meets efficiency in plastic part finishing with CNC robotic trimming, ensuring accuracy, consistency, and on-time delivery for superior results.

Thermoforming plastics requires using large sheets of plastic to fit around a custom-designed tool to create a shape that meets our clients’ exact needs and specifications. However, once the plastic is molded and shaped after thermoforming, it’s not ready to use just yet. In many cases, holes, windows, and other spaces need to be cut out of the shape, while any excess plastic that is not part of the design still has to be trimmed away.

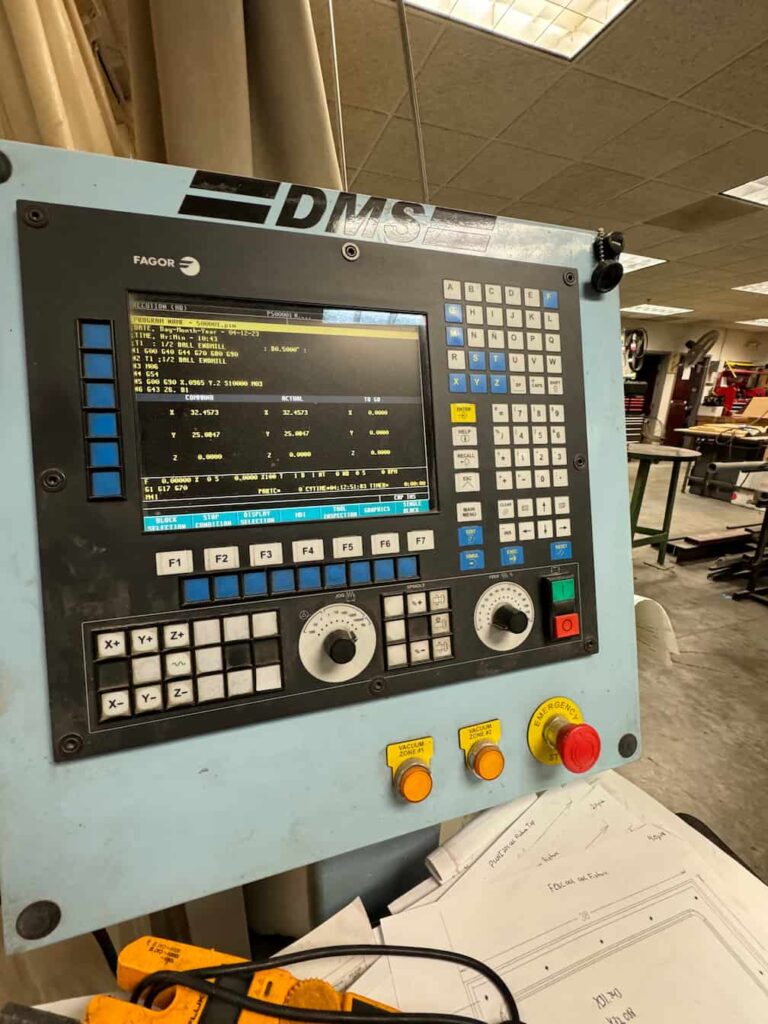

Because accuracy, precision, and consistency are essential in custom plastics manufacturing, we don’t rely on human skill to do the trimming. Instead, we employ CNC trimming equipment to ensure that not only the outline is trimmed perfectly, but any hole placements, trim angles, or window openings within the form are accurately and consistently cut.

CNC Trimming for Thermoformed Plastics

Computer numerical control, or CNC machinery allows us to use pre-programmed computer software to direct the movements of the machine. With CNC trimming, this means we program the machine to route and trim your plastic products in fine detail and within very specific tolerances. To maintain the specifications determined during the design and prototyping phase, we use the 3D modeling and CAD software to program the machine with the final 3D CAD drawings.

We utilize 5-axis CNC trimming equipment which is considered to be the best CNC robotic trimming equipment available. With five rotational axes, it offers multidimensional rotation and tool movement through the use of a routing bit mounted at the tip of a high-speed, articulating spindle. This is often the technology utilized in aerospace products and medical prosthetics due to the clean edges, precision and speed it provides, which is why we provide it for our customers.

Using CNC and Robotic Trimming for Custom Plastic

Robotic trimming requires high attention to detail from our CNC engineering team to ensure the final product meets the approved specifications. They plan the process and ensure accurate coding is entered into the CNC equipment. After the thermoforming process is complete, we vacuum clamp the newly formed plastic to a router fixture that was cast from the thermoforming tool. In some cases, to meet the most stringent requirements, these fixtures are CNC machined for the highest geometric precision.

Once it’s affixed with vacuum clamps, our team of CNC engineers oversee the trimming process to ensure accuracy and efficiency, while determining if any in-process adjustments are implemented. In the event any adjustments need to be made, our engineers can do them quickly through our advanced ECO management system so lead times aren’t affected.

Benefits of Partnering with Advanced Plastiform Inc.

Attention to Detail That Drives Results

Every project is handled with precision. We focus on the details that matter most to you—dimensional accuracy, material performance, and consistency—so your plastic parts perform as designed.

Consistency That Exceeds Expectations

Our team understands the demands of your business and delivers accordingly. Whether it’s a complex component or a tight turnaround, we adapt quickly to meet your project’s needs without compromising quality.

Collaborative, Customer-Focused Approach

Our engineers, project managers, and customer service professionals work closely with you throughout production. Open communication ensures that your goals are met efficiently and transparently.

All Expertise Under One Roof

From design engineers to sales and ownership, everyone is on-site and engaged in daily operations. This structure eliminates delays, streamlines problem-solving, and provides immediate answers at every stage of your project.

Daily Commitment to Quality and Communication

Each morning, our production team meets to review active projects, address challenges, and align on priorities. This proactive approach keeps every job on track and ensures nothing falls through the cracks.

Decades of Proven Experience

With over 35 years of experience in thermoforming and injection molding, we’ve built lasting relationships across industries by delivering reliable results, innovative solutions, and outstanding customer support.

Flexible Manufacturing Capabilities

Our dual expertise in thermoforming and injection molding allows us to choose the best process for your needs—optimizing production efficiency, cost, and quality from prototype to full-scale manufacturing.

Contact API for Your High-Quality Custom Plastics Manufacturing

Advanced Plastiform, Inc. are leaders in the injection molding and thermoforming industry because our attention to detail doesn’t stop once the plastic is shaped. We prioritize every step of the manufacturing process from design to delivery while investing in innovative, high-end manufacturing equipment and machines to provide the best quality plastics.

CNC trimming is just one of the many value-added processes we use to ensure the quality of our product and our performance. We’re pleased to provide our custom plastic manufacturing services to businesses in North Carolina, South Carolina, Tennessee, Pennsylvania, Maryland, Georgia, and Virginia.