3D Printing Plastics

Efficiency redefined with advanced 3D printing technology. Ensuring quality and accuracy, backed by proven success in custom plastic manufacturing.

At Advanced Plastiform, Inc., we are dedicated to designing and manufacturing the highest quality plastics while providing our customers with fast lead times and low per-unit prices. We know that in order to do this, it’s essential to understand the latest innovations and specialize in new technology. In addition to being a leader in thermoforming and injection molding, we also provide 3D printing services.

Understanding 3D Printing Plastics

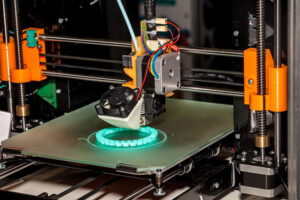

To print a three-dimensional object, our experienced team starts by designing a 3D model using computer-aided design, or CAD. Once the 3D model meets the necessary specifications, the digital file is prepared to be printed, also called “slicing.” Slicing means the 3d model is digitally divided into hundreds, or even thousands, of thin, horizontal layers. This step is necessary in the printing process.

While it’s generally called 3D printing, the technical term is “additive manufacturing.” Unlike paper printing that rolls out at once, a 3D print is created by a machine laying down the thin, single layers that were “sliced” into the 3D model. Those layers are laid on top of one another, building the object from the surface up, until the plastic piece is complete.

3D Printing a Product Prototype

We use 3D printing most often for product prototyping, which is an essential part of our manufacturing process whether your plastic components will be created using thermoforming or injection molding. Our design team and production engineers bring the 3D model to life by creating a prototype, or a preliminary physical model, before the final manufacturing begins. This guarantees you are satisfied with how the product will look and function in mass production, while our engineering team will have an accurate physical form for which to create tooling and molds.

Using a 3D printer makes the prototyping process less expensive and much faster than traditional methods. This allows us to move onto the next steps, tooling and manufacture faster, providing you with a faster lead time and a lower overall cost!

Choosing Additive Manufacturing

While we use thermoforming and injection molding to manufacture the majority of our plastics, we can also work with you to determine if additive manufacturing is the better method.

Benefits of Additive Manufacturing

- Highly customizable - Because the digital 3D model can be adjusted and altered, every item can be customized without impacting manufacturing costs.

- Complex geometry - While thermoforming and injection molding are limited in the angles and shapes produced, 3D printing can fabricate any kind of angle or shape. Because the printing method is the same for simple designs as it is for complex shapes, there’s no extra cost for complex printing.

- Low startup costs - One of the more expensive aspects of thermoforming and injection molding is the tooling cost. Additive manufacturing doesn’t require any mold or tooling, so that cost is eliminated, and the only costs are associated after design is with material, printing time, and post-processing.

Generally, our design and engineering team recommend 3D printing as a final manufacturing method for plastics that have very complex geometric design requirements and low volume orders requiring a short turnaround time.

Uses for 3D Printing

As 3D printing becomes more affordable and efficient, more industries are choosing it for their custom plastics.

Some of the most common industries who use 3D printing include:

- Aerospace

- Automotive

- Robotics

- Tooling

- Medical

- Design

- Cinema

- Education

Materials Used in 3D Printing

Plastics used in 3D printing are either thermoplastics which melt as they are heated and can be reshaped and remolded without changing the physical properties, or thermosets, which contain polymers that cross-link when heated to create a chemical bond and can’t be reheated. At API, we have a wide variety of thermoplastic materials available to create your design, including:

Contact Us to Learn More about 3D Printing

Since we opened our doors in 1989, we were dedicated to providing the best service to our clients across the Southeast and Mid-Atlantic regions by ensuring high-quality, custom plastics with a low per-unit cost and a faster lead time. To maintain that level of service, we know innovation is essential, which is why we use the latest additive manufacturing technology at our plastics manufacturing company.

To learn more about our 3D printing and rapid prototyping, reach out to us today! Our Zebulon, North Carolina headquarters gives us a central location to deliver to seven states, including North Carolina, South Carolina, Pennsylvania, Maryland, Tennessee, Georgia, and Virginia.