Prototyping Custom Plastics

From concept to reality, Advanced Plastiform delivers high-quality custom plastic prototypes with unmatched precision, efficiency, and consistency.

Prototyping Custom Plastics

At Advanced Plastiform, Inc. we specialize in manufacturing custom plastics for a variety of industries, including automotive, medical supply, and telecommunications. Our customers depend on us for more than fast lead times and low prices. They look to us to provide them with accurate, functional plastics that meet their exact needs. That’s why product prototyping is such an essential part of our comprehensive design and development process.

Understanding Plastic Prototyping

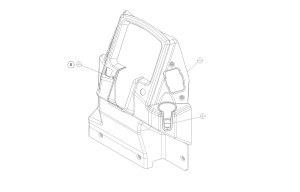

A prototype is the first physical model created from a concept or design. At API, creating a prototype of a customer’s design allows you to see and examine a functional, working model of the plastic product needed. This gives you the opportunity to see how it works and test its functionality while our plastics engineering team uses it to design tooling and prepare for the mass manufacturing process.

Bringing a 3D Model to Life

Before the prototyping phase, the first phase of our plastics development process involves our team working with our clients to create a 3D model of the exact product, part, or component needed. Using your CAD drawings or models, we can then take the digital file and, with our innovative 3D printing technology, print out your product prototype.

Utilizing this technology makes the prototyping phase fast and inexpensive, allowing us to move onto the next stage of tooling design and manufacturing more quickly while reducing the overall costs.

Testing a Prototype

Once we print out the product prototype, we work with you to make any adjustments. During this time, our engineers can help you troubleshoot issues and determine options to improve the design. This is also a period where we make final determinations of which thermoplastic materials should be used and whether thermoforming or injection molding is ideal. Without a product prototype, going from design to tooling could lead to serious flaws in the final manufactured products.

Prototyping Tooling

With an approved prototype, we are able to move onto to the tooling phase where we begin designing the molds, components, and machinery necessary to achieve the accurate form and function. Because making sure the tooling we design is cast correctly, we also have a prototype phase here, too!

In most product development projects, we’ll produce prototype tooling right here at our manufacturing location so we can quickly produce a small quantity of test products. This temporary tooling, cast from affordable aluminum, lets us test the plastics before committing to the final aluminum, steel, or copper alloy tooling which is much more expensive.

Once all prototyping steps are complete, we are able to move into final tooling design, which is the last step needed before mass production.

Contact Us to Learn More About Prototyping Custom Plastics

At Advanced Plastiform, Inc. we take pride in offering superb customer service by combining the low prices and fast lead times you want with the durable, high-quality custom plastics you need. To learn more about our services or to discuss a quote, contact us today! Our Zebulon, North Carolina headquarters gives us a central location to deliver to seven states, including North Carolina, South Carolina, Pennsylvania, Maryland, Tennessee, Georgia, and Virginia.