Injection Molding Company for High-Quality Parts

Delivering precision plastic injection molding services to create custom parts with speed and accuracy to businesses in North Carolina, South Carolina, Virginia, Georgia, Tennessee, Maryland and Pennsylvania.

Contact Advanced Plastiform, Inc.

Let Us Know How We Can Help!

"*" indicates required fields

Your Trusted Company for High-Quality Plastic Injection Molding Services

At Advanced Plastiform Inc., we specialize in delivering reliable, cost-effective custom injection molding services tailored to meet the demands of high-volume production and complex part designs.

With our state-of-the-art presses, our injection molding company is able to offer shorter lead times and lower per-unit pricing without compromising quality, accuracy, or service. With over three decades of experience, advanced equipment, and a commitment to customer satisfaction, we help businesses across a wide range of industries bring their custom molded products to life with precision, consistency, and efficiency.

Understanding Injection Molding for Custom Plastics

Custom plastic injection molding is a highly efficient manufacturing method used to produce large quantities of uniform, durable plastic parts with exceptional precision. Known for its ability to create complex plastic components at scale, the injection molding process is widely used across multiple industries such as automotive, medical, and consumer products. As materials and technology continue to advance, the future of injection molding promises even greater design flexibility, faster production speeds, and more sustainable solutions for modern manufacturing needs.

Benefits of Partnering with Advanced Plastiform Inc.

Attention to Detail That Drives Results

Every project is handled with precision. We focus on the details that matter most to you—dimensional accuracy, material performance, and consistency—so your plastic parts perform as designed.

Consistency That Exceeds Expectations

Our team understands the demands of your business and delivers accordingly. Whether it’s a complex component or a tight turnaround, we adapt quickly to meet your project’s needs without compromising quality.

Collaborative, Customer-Focused Approach

Our engineers, project managers, and customer service professionals work closely with you throughout production. Open communication ensures that your goals are met efficiently and transparently.

All Expertise Under One Roof

From design engineers to sales and ownership, everyone is on-site and engaged in daily operations. This structure eliminates delays, streamlines problem-solving, and provides immediate answers at every stage of your project.

Daily Commitment to Quality and Communication

Each morning, our production team meets to review active projects, address challenges, and align on priorities. This proactive approach keeps every job on track and ensures nothing falls through the cracks.

Decades of Proven Experience

With over 35 years of experience in thermoforming and injection molding, we’ve built lasting relationships across industries by delivering reliable results, innovative solutions, and outstanding customer support.

Flexible Manufacturing Capabilities

Our dual expertise in thermoforming and injection molding allows us to choose the best process for your needs—optimizing production efficiency, cost, and quality from prototype to full-scale manufacturing.

Injection Molding vs Thermoforming

When choosing between injection molding versus thermoforming methods to produce plastic parts, the best choice depends on your project’s needs.

Choose Injection Molding When:

- You need high-volume production

- Parts require complex shapes or fine details

- Tight tolerances and consistency are important

- You're producing small to medium-sized components

- Long-term cost efficiency is a priority

Choose Thermoforming When:

- You need larger parts or simple shapes

- Lower tooling costs and faster setup are desired

- You’re working with low to mid-volume production

- Speed to market is more important than fine detail

- Flexibility in design adjustments is needed

Plastic Injection Molding Capabilities

| Industry Focus | Aerospace, Automotive, Communication, Construction, Electrical, Electronic, Optical |

|---|---|

| Material | ABS, Acetyl, Acrylic, Copolymer Polypropylene, HDPE/LDPE, Nylon, PEEK, Vectra, PET, Polycarbonate, Polyester, Polypropylene, Polystyrene, Polyurethane, ULTEM, Liquid Crystal Polymers |

| Product Capabilities | Medium-sized parts, Micro parts, Miniature parts, Small-sized parts |

| Services | Insert Molding, Over Molding, Mold Making, Kanban Program, Inventory Managed Shipment |

| Production Volume | Low Volume, Small Runs, High Volume, Large Runs, Sample Runs |

| File Formats | AutoCAD (DWG), IGES, JPEG or JEPG, PDF, Solid Works (SLDPRT, SLDDRW, SLDDRT) |

| Shot Size | 5mg (min) – 450g (max) |

| Clamping Force | 17 tons (min) – 220 tons (max) |

| Number of Cavities | 1 cavity (min) – 16 cavities (max) |

| Tolerance (+/-) | Down to 0.0001 in. |

At Advanced Plastiform Inc., we’ll help you select the best method to match the design, budget, and production needs for complex projects and precision parts.

Advantages of Custom Injection Molding

Custom injection molding offers a range of benefits that make it the preferred manufacturing process for many industries requiring high quality products. Our plastic mold manufacturing company serves clients looking for precision, scalability, and opportunities to reduce costs of injection molding manufacturing while still maintaining superior quality control.

High-Volume Production Efficiency

Once the mold making process is complete, injection molding allows for rapid production of thousands—or even millions—of identical parts, reducing per-unit costs and improving turnaround times.

Precision and Consistency

Injection molding delivers tight tolerances and uniformity across all plastic parts, making its molding capabilities ideal for components where accuracy is critical, such as in medical devices or automotive applications.

Design Flexibility

With custom two-sided molds, manufacturers can produce complex geometries, varying wall thicknesses, and detailed features that are difficult to achieve with other methods of product design.

Minimal Material Waste

The injection molding process produces little to no excess material, and many thermoplastics used can be recycled, making it a more sustainable option for manufacturers focused on reducing waste and increasing efficiency.

Durability and Strength

Insert molding for plastic parts can be reinforced with fillers or made from high-performance thermoplastics to meet demanding mechanical, thermal, or chemical requirements. With innovative solutions and quality control, injection molding builds products made to last.

Repeatable and Scalable

Whether you need a few prototypes, reliable small production runs, or millions of end-use products, injection molding ensures repeatability at every scale, maintaining product integrity over time.

Cost Effective Solutions

Injection molding offers excellent cost efficiency for high-volume production, as the initial investment in tooling is offset by low per-unit costs over time. Once the mold is created, parts can be produced rapidly and consistently with minimal waste, making it ideal for long-term savings.

Advanced Plastiform's Injection Molding Process

At Advanced Plastiform Inc., we follow a comprehensive, customer-focused injection molding process designed to deliver precision, efficiency, and high-quality results from start to finish.

Consultation and Project Planning

Our process begins with a detailed consultation to understand your product requirements, including function, material needs, production volume, and budget. We help determine whether injection molding is the right fit or if thermoforming may be more efficient for your goals.

Material Selection and Design Assistance

Our engineers work with you to select the ideal thermoplastic for your application, balancing strength, flexibility, and cost. From there, our design team creates a 3D CAD model to visualize the part before tooling.

Prototyping and Testing

Using your approved design, we develop a prototype to verify functionality, performance, and aesthetics. This step allows for early adjustments and ensures confidence before moving into full production.

Tooling Fabrication

Once the prototype is finalized, we create custom tooling using high-grade materials suited to your production volume and part complexity. Our relationships with both domestic and international injection molding tooling partners allow us to reduce lead times and control costs.

Production and Quality Control

Using advanced injection molding presses (up to 610 tons), we begin full-scale production. Throughout the run, we monitor for consistency, precision, and durability, making any necessary adjustments to ensure every part meets your exact standards.

Secondary Finishing and Value-Added Services

After molding, parts can undergo secondary processes such as CNC machining, painting, coating, or assembly. We also offer packaging, warehousing, and logistics solutions to streamline your supply chain.

This end-to-end process ensures your injection molded parts are delivered on time, on budget, and on spec—every time.

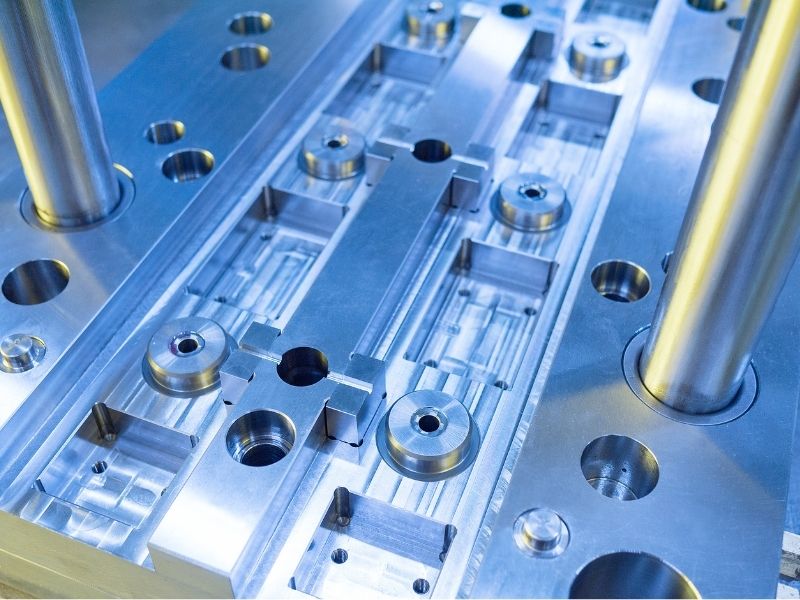

Injection Mold Tooling Capabilities

At Advanced Plastiform Inc., our injection mold tooling capabilities are engineered to support both simple and highly complex part designs while minimizing lead times and maximizing part quality. Tooling is one of the most critical stages in the injection molding process, and our team works closely with top-tier tooling manufacturers—both domestic and international—to deliver durable, precise molds that perform across long production runs.

High Quality Tooling Materials

We offer custom tooling solutions using robust materials like hardened steel, aluminum, and copper alloys, selected based on your production volume, design complexity, and budget requirements. Whether you're producing a limited number of prototypes or millions of high-performance parts, our tooling can accommodate single- or multi-cavity designs for fast, scalable manufacturing.

Key Features of Our Tooling Capabilities Include:

- Custom-built molds designed for part consistency and precision

- Support for complex geometries, undercuts, and varying wall thicknesses

- Single cavity and multi-cavity mold options to increase output and reduce cost

- Rapid turnaround times due to multiple trusted tooling sources

- Tool maintenance and storage for ongoing or future production runs

Transfer Tooling Solutions

Tooling transfer allows you to move your existing injection mold to a new manufacturer—saving time and money while improving production outcomes. At Advanced Plastiform Inc., our injection molding experts inspect, test, and adjust transferred molds to ensure a seamless fit with our equipment and processes.

Choose Tooling Transfer When:

- Your current supplier is causing production delays

- You're seeing inconsistent part quality

- You need better pricing or customer support

- You want to consolidate manufacturing under one trusted partner

Our strategic approach to tooling ensures that every mold we produce is built for long-term value—delivering high accuracy, tight tolerances, and efficient performance throughout the product lifecycle.

Thermoplastics We Work With

Choosing the right material is essential to the success of any injection molding project. Our injection molding company works with a wide range of high-performance thermoplastics to ensure your parts meet the exact requirements for durability, flexibility, appearance, and function. Each of these common plastics used in injection molding offers unique characteristics that make it well-suited for injection molding and high-volume production.

ABS – Acrylonitrile Butadiene Styrene

ABS is a tough, impact-resistant thermoplastic that offers excellent dimensional stability and surface finish. Its strength and durability make it ideal for applications in automotive, electronics, and consumer products. ABS performs exceptionally well in injection molding due to its easy flow and ability to reproduce fine details.

Acrylic

Acrylic is known for its clarity, UV resistance, and polished appearance, making it perfect for optical parts, displays, and transparent housings. It molds well under high pressure and provides a glass-like finish that holds up in outdoor or light-exposed environments.

HMWPE – High Molecular Weight Polyethylene

HMWPE is a high-density, abrasion-resistant plastic often used in applications that require impact resistance and chemical stability. It’s a great choice for industrial and material handling components, though it requires specialized tooling due to its low friction and high toughness.

HIPS – High Impact Polystyrene

HIPS is a lightweight yet rigid thermoplastic that provides good impact resistance and is easy to process. It’s often used for packaging, enclosures, and displays. HIPS offers excellent mold-ability and works well for detailed parts requiring consistent surface finish.

TPO – Thermoplastic Polyolefin

TPO is a flexible, weather-resistant plastic commonly used in automotive and construction applications. It’s particularly beneficial in injection molding for products exposed to UV light and temperature changes, offering long-term durability without cracking or fading.

PP – Polypropylene

Polypropylene is a versatile, fatigue-resistant plastic known for its chemical resistance and flexibility. It’s widely used in packaging, medical components, and consumer goods. In injection molding, PP flows easily and cools quickly, making it efficient for high-volume runs.

PC – Polycarbonate

Polycarbonate is a strong, heat-resistant plastic that offers excellent impact strength and transparency. It’s used in safety equipment, electronics, and lenses. PC is ideal for injection molding when strength and clarity are equally important.

PVC – Polyvinyl Chloride

PVC is a dense, durable plastic with outstanding chemical and weather resistance. It’s suitable for both rigid and flexible parts, including piping, enclosures, and protective components. PVC performs well in injection molding but requires controlled temperatures and tooling to prevent degradation.

Industries Served by Our Injection Molding Company

Advanced Plastiform Inc. provides high-quality plastic injection molding services to a wide range of industries that demand precision, durability, and cost-effective production. Our extensive experience and engineering expertise allow us to develop custom molded parts that meet strict performance standards across diverse applications—from automotive components to medical housings and more.

No matter the industry, we deliver consistency, scalability, and tailored solutions that help our clients succeed.

Automotive Injection Molding

We manufacture precise, durable parts for the automotive injection molding, including interior trim pieces, knobs, housings, and clips. Our ability to produce high volumes of identical parts with tight tolerances makes us a trusted partner for Tier 1 and Tier 2 automotive suppliers.

Medical and Healthcare

From enclosures and instrument housings to disposable components, we support the medical industry with clean, precise injection molded parts. Our medical injection molding materials are chosen for their biocompatibility and performance under strict hygiene and regulatory standards.

Construction and Farm Equipment

We produce rugged, high-strength plastic components used in heavy-duty environments such as panels, brackets, and protective covers. Injection molding allows for efficient manufacturing of parts that endure vibration, moisture, and mechanical stress in the field.

Transportation

Our molded parts are used in a variety of transportation applications including transit vehicle interiors, enclosures, and mechanical parts. We provide reliable solutions for OEMs that require lightweight, strong, and weather-resistant plastics.

Refrigeration and HVAC

We manufacture internal and external components for refrigeration units and HVAC systems, including ducting, fan housings, and vent panels. Injection molding ensures these parts maintain structural integrity across temperature fluctuations and daily use.

Recreational Vehicles and ATVs

Plastic parts for RVs, ATVs, and powersports vehicles need to be durable, lightweight, and UV-resistant. We provide custom molded pieces for body panels, interior components, and housings that enhance performance and style.

Shipping and Logistics

We create plastic containers, dividers, and pallets used in warehousing and shipping. Our injection molded solutions are designed for strength, stackability, and long-term reuse, helping companies optimize material handling processes.

Furniture and Home Goods

Injection molding supports furniture manufacturers with decorative trim pieces, hardware, and ergonomic components. We offer aesthetically pleasing and structurally sound plastic parts that fit seamlessly into furniture designs.

Filtration and Water Systems

We produce molded parts for water purification and filtration systems, including filter housings, valves, and internal supports. Our plastics offer chemical resistance and tight sealing properties critical for performance in fluid systems.

Material Handling

From bins and trays to protective inserts and liners, we help material handling operations improve efficiency and safety. Our parts are designed for impact resistance and long-term use in demanding industrial environments.

Telecommunications

We support telecom companies with precision plastic housings, cable management components, and protective enclosures. Our molded parts are built to shield sensitive equipment while maintaining accessibility and durability.

Injection Mold Classifications

Injection mold classification refers to the standardized system used to categorize molds based on factors such as production volume, material type, tooling durability, and expected lifespan. These classifications help manufacturers and engineers determine which type of mold is most suitable for a specific application—whether it’s for a short prototype run or high-volume production runs.

5 Primary Mold Classes:

- Class 101: High-Volume Production Molds

- Class 102: Medium to High-Volume Production Molds

- Class 103: Medium-Volume Production Molds

- Class 104: Low-Volume Production Molds

- Class 105: Prototype Molds

Each class is defined by specific tooling requirements, expected cycle counts, and maintenance needs. Selecting the correct mold class is critical to balancing cost-efficiency, product quality, and long-term production goals. To explore each classification in more detail, visit our Injection Mold Classifications guide.

Contact Our Custom Plastic Injection Molding Company for a Quote

For over 30 years, our North Carolina injection molding company has been a leading supplier of custom plastic parts at competitive prices. With a proven track record of expertise and personalized service, our plastic engineering services produce high-quality parts that offer innovation, quality assurance, and timely delivery across industries.

Proudly serving North Carolina, South Carolina, Pennsylvania, Maryland, Tennessee, Georgia, and Virginia,, we are your perfect partner for top-quality, custom injection molding services.

Get started on your project by contacting us at 919-404-2080 or filling out our easy-to-use online contact form today.