Frequently Asked Questions About Vacuum Forming Plastic

Vacuum Forming FAQs

Thermoforming plastic manufacturing is an essential part of the production process for many important industries around the world. The concept of heating and molding plastic sheets is one of the most effective, affordable, and fast ways to get a product made. It’s also one of the most efficient ways to produce parts and components used in the packaging, telecommunication, medical, and automotive industries, among many others.

While there are several subsets of plastic thermoforming, such as pressure forming, when it comes to low cost and high production speed for low-volume manufacturing of high-quality components, vacuum forming offers many advantages.

Our vacuum forming production experts at Advanced Plastiform, Inc. are here to answer all of the frequently asked questions about vacuum forming and show why it’s considered the simplest form of thermoforming, using just a plastic sheet and mold to create a prototype or component for products.

Vacuum Forming Plastic FAQs

Q: What is vacuum forming?

Answer: Vacuum forming is a simple manufacturing process that is a subset of thermoforming. With vacuum forming, a sheet of plastic is heated to become pliable before using vacuum technology to suction the plastic to a mold. The vacuum removes all of the air from between the flexible plastic sheet and the premade mold, allowing the heated plastic to form tightly against the mold’s custom-made shape for a prototype of the product part.

Q: How long has vacuum forming been around?

Answer: The thermoforming concept of vacuum forming was developed in the 1950s, with the very first vacuum forming machine being patented and used for mass production in 1964. However, other forms of thermoforming were being used prior to the years of consumer product booms, with thermoforming dating as far back as the late 19th Century.

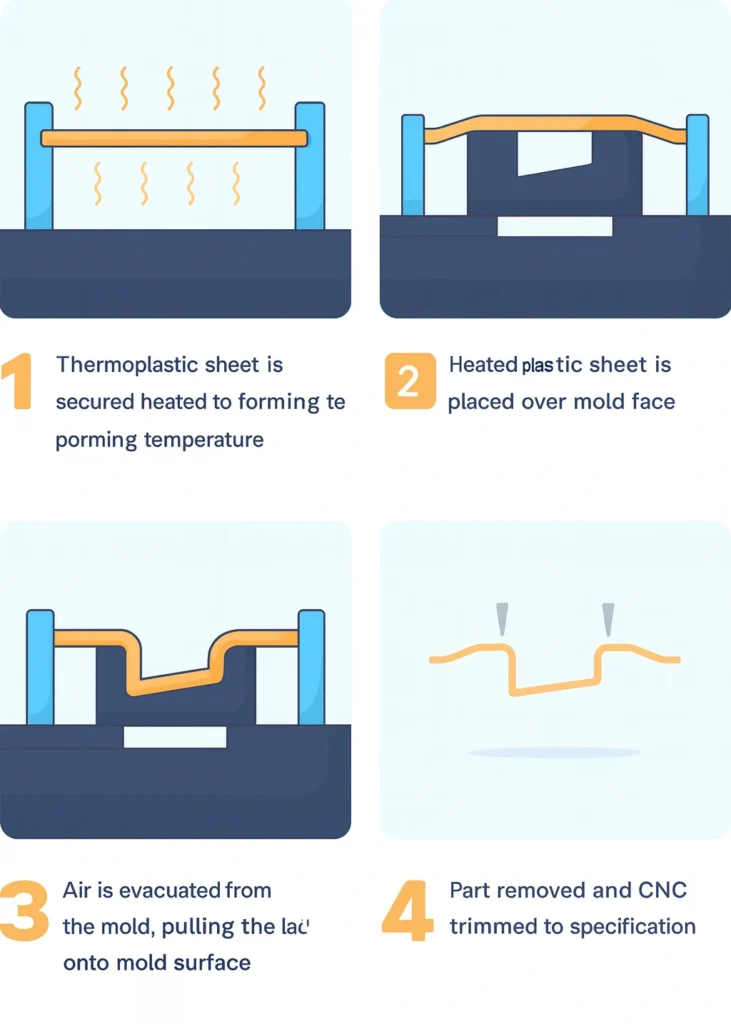

Q: What is the vacuum-forming process?

Answer: Plastic vacuum forming has been one of the go-to manufacturing processes for low volume, high-quality items for decades due to its simplicity in forming plastic to a pre-made mold through the use of an air vacuum.

Once the mold is created, the step-by-step process of vacuum forming is as follows:

- The mold is placed within the vacuum former.

- A plastic sheet is clamped above the mold.

- The radiant heater heats the plastic from above, making it pliable.

- The softened plastic is then placed over the mold.

- The vacuum former is then turned on, removing air from below, out of the machine and allowing the heated plastic to tightly form around the mold.

- Once cooled, the mold and plastic are removed from the machine. The result is a perfectly molded plastic form that will be trimmed and finished to build products.

Q: What’s the difference between vacuum forming and pressure forming?

Answer: Pressure forming follows the same steps as vacuum forming, but differs in the way that the softened plastic sheet is fit to the mold. Where vacuum forming uses only vacuumed air removal to suction the plastic the mold, pressure forming uses a more enhanced technique of the same vacuum technology paired with air pressure from above to even more precisely mold the form.

Q: What are the benefits of vacuum forming?

Answer: The number one benefit of using vacuum forming is that it is cheap to produce a low volume of parts quickly, but there are other benefits as well.

The benefits of vacuum forming are:

- Capable of making highly detailed products of small, medium, and large sizes.

- Large items cost less when vacuum-formed over other methods of thermoforming.

- Fast speeds for low-volume production.

- Customizable for a variety of colors and textures of parts.

- Creates visually appealing components of high quality.

- Low tooling costs.

- Consistent output of parts from batch to batch.

- Excess plastic can be recycled into plastic sheets for future production needs.

Q: What materials can be used in vacuum forming?

Answer: Vacuum forming requires the use of thermoplastics that become easily pliable when softened with heat. Additionally, plastics that have high resistance to flames, chemicals, and even water is used in vacuum forming.

Examples of types of materials used for vacuum forming are:

- Acrylics

- Acrylonitrile Butadiene Styrene (ABS)

- Acrylonitrile Styrene Acrylate (ASA)

- High Impact Polystyrene Sheeting (HIPS)

- Polycarbonate (PC)

- Polyvinyl Chloride (PVC)

While a variety of different plastic choices exist, we often see HIPS used most commonly for high-quality, durable parts made through vacuum forming.

Q: Can you vacuum form clear plastic?

Answer: Yes! Clear plastic sheets can be formed onto molds via vacuum forming. In fact, the food industry uses the vacuum-forming manufacturing technique to create containers, lids, and clear insert molds made for food packaging.

Q: How thick a sheet of plastic can you vacuum form?

Answer: Vacuum forming can be done on sheets of plastic between 0.0005 to 0.50 inch thick, although some machines used for prototyping may have restrictions that can only use plastic sheets up to 0.25 inch thick.

Q: What products can be created from vacuum forming?

Answer: The vacuum-forming manufacturing process is responsible for the creation of hundreds of everyday products. Because of the low cost and high-efficiency levels, companies turn to a company who uses vacuum forming to create a number of household items. From large-scale items like the trays and linings in bathtubs and refrigerators, to smaller items like plastic eating utensils and food storage containers, it’s very likely your home is filled with products whose components were vacuum formed.

Other industries and products that commonly use vacuum forming are:

- Electronic devices like thermostats.

- Agriculture and farming vehicle and equipment parts.

- Acrylic “glass” used in greenhouses.

- Vehicle dashboards, bumpers, headlight covers and more.

- Food industry plastics such as candy and chocolate mold trays.

- Food storage containers.

- Clear plastic sign holders.

- Parts for medical equipment like x-ray machines, CT scanners, and MRI machines.

Q: Is vacuum forming better for low-production or high-production manufacturing?

Answer: The biggest advantage of using vacuum forming compared to other thermoforming processes is that it is cheap and fast. If you are looking to produce high-production levels of items on a mass scale, injection molding or other types of thermoforming would be better options.

Vacuum Forming Plastic Manufacturing with Advanced Plastiform, Inc.

Is your industry in need of a fast, cost-efficient manufacturing process? Advanced Plastiform Inc. uses vacuum forming and other heavy-gauge thermoforming manufacturing processes to build high-quality, durable plastic components and parts. These vacuum-formed parts then go on to build usable products for appliances, equipment panels, everyday objects, and more.

Our plastic thermoforming company serves customers in North Carolina, South Carolina, Maryland, Pennsylvania, Georgia, Tennessee, and Virginia with the manufacturing of products and parts through vacuum forming. To inquire about vacuum forming, other subsets of thermoforming, or injection molding, call us today at 919-404-2080 or fill out our contact form to get started.