Learn how insert molding and overmolding are performed and their benefits and challenges to help…

Understanding the Difference Between Overmolding versus Insert Molding

In the injection molding process, the method of overmolding bonds a second plastic layer onto a molded substrate to add soft-touch grip, sealing, and aesthetic accents. Another method is through insert molding, which encapsulates a preformed insert—often metal or a component—inside plastic to add strength, threads, or thermal functionality.

Choosing between overmolding vs insert molding manufacturing processes for custom plastics means looking at how they each add performance, comfort, and durability to part production.

Join our injection molding company as we explore overmolding vs insert molding—including what each method entails, where it excels or falls short, and how they differ on cost, lead time, materials, and risk.

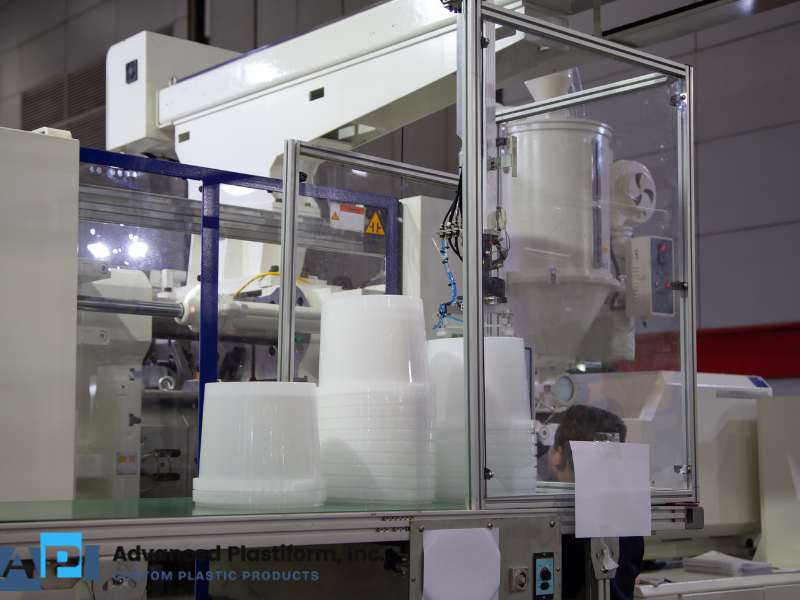

Overmolding In The Injection Molding Process

Overmolding bonds a second material, typically a softer Thermoplastic Olefin (TPE) or a contrasting rigid resin, over the substrate—a pre-molded, rigid base—that provides the part’s structure. Shot first and then overlaid in a second shot, the two materials become a single component with integrated grips, seals, color accents, and other features.

Benefits of Overmolding

Overmolding shines when you need comfort, sealing, or brand differentiation in one cohesive plastic part:

- Improved Grip and Ergonomics: Soft-touch overmolds add tactile comfort and reduce user fatigue in handheld tools and consumer goods.

- Integrated Sealing: A soft elastomer layer can create water, dust, or vibration seals without separate gaskets.

- Reduced Assembly Steps: Multi-material features form in the press, eliminating adhesives or secondary fastening.

- Enhanced Aesthetics and Branding: Contrasting colors, textures, and logos can be molded-in for a premium look.

- Vibration Damping and Noise Reduction: Softer materials absorb shock and buzz in appliances, power tools, and electronics.

- Part Consolidation: Combining functions in one component simplifies supply chains and quality checks.

- Strong Chemical Bonds: Proper resin pairing and surface prep create durable chemical or mechanical bonds between layers.

Drawbacks of Overmolding

There are tradeoffs to consider before committing to overmolding during the injection molding process:

- Tighter Material Compatibility Rules: Not all resins bond well; material pairing and surface energy must be validated.

- More Complex Tooling: Two-shot or sequential tooling increases mold cost and process setup complexity.

- Higher Cycle Time Potential: Multiple shots or preheating steps can lengthen each cycle relative to single-shot molding.

- Risk of Delamination: Inadequate temperatures, contamination, or poor design can weaken the interface over time.

- Narrower Processing Window: Temperatures, pressures, and venting must be tuned to protect the substrate while shaping the overmold.

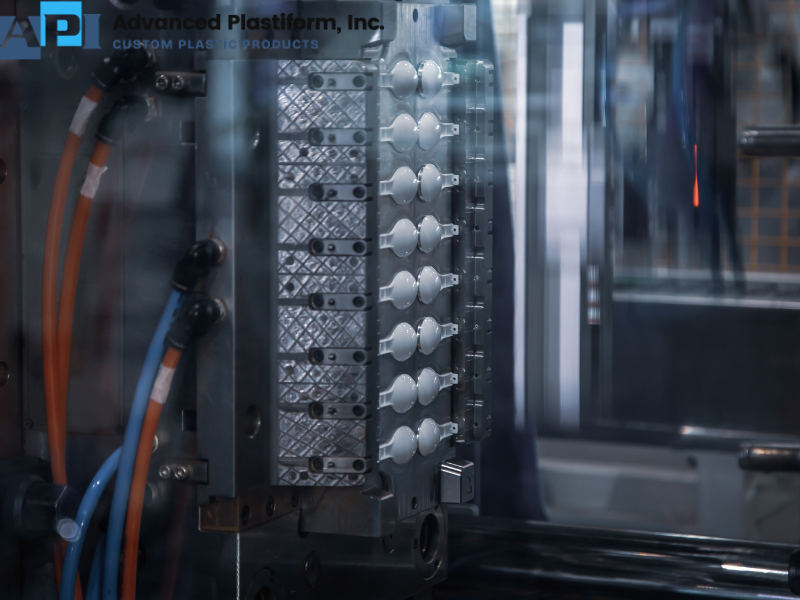

Insert Molding In The Injection Molding Process

Insert molding encapsulates a preformed insert—typically metal threads, pins, contacts, magnets, or ceramics—inside molten plastic to create one integrated plastic component. The insert is placed in the mold (by hand, fixtured automation, or robotics), and the resin flows around and through its retention features to form a mechanical and/or thermal/electrical bond.

The result is a single molded part with embedded strength, precise fastening points, and functional elements like conductivity or wear surfaces—without secondary assembly.

Benefits of Insert Molding

Insert molding is ideal when your design demands structure, fasteners, or conductive features:

- Embedded Strength and Wear Surfaces: Metal inserts reinforce screw points, pivots, and load paths for longevity.

- Integrated Threads and Fasteners: Captured nuts or studs provide repeatable, high-torque assembly without secondary operations.

- Electrical or Thermal Functionality: Contacts, sensors, and heat-spreading components can be molded-in to save space.

- Improved Alignment and Precision: Locating features on inserts maintain dimensional accuracy across high volumes.

- Assembly Reduction: Fewer press-fit or ultrasonic staking steps lower handling costs and QA risk.

- Material Flexibility: Plastic can be optimized for weight and cost while inserts deliver the needed strength or function.

Drawbacks of Insert Molding

Be aware of these insert molding process constraints:

- Manual or Automated Loading Needed: Inserts must be placed accurately, adding fixtures, robots, or labor.

- Increased Cycle Time Risk: Loading and verifying each insert can slow throughput relative to standard molding.

- Potential Knit Lines and Stress Risers: Flow around inserts requires careful gate, vent, and rib design to avoid weakness.

- Thermal Mismatch Concerns: Different coefficients of thermal expansion can stress interfaces if not engineered properly.

- Supply Chain Dependence: Quality and availability of inserts affect yields and production scheduling.

Comparing Overmolding vs Insert Molding Methods

When planning your plastic injection molding project, compare overmolding vs insert molding by what your part truly needs—soft-touch surfaces and sealing (overmolding) versus embedded strength, threads, or conductivity (insert molding).

From lead time and tooling to injection molding costs per unit, materials, and reliability, the processing choice between overmolding vs insert molding should align with your performance targets, production volume, and downstream assembly plan.

Lead Times

Overmolding often requires multi-shot or sequential tooling and bonding validation, which can extend development. Insert molding typically uses a single mold but adds time for insert sourcing and load/verification fixtures.

For pilot runs, insert molding can be faster if inserts are readily available; for mature programs, well-dialed overmolding can rival insert molding throughput.

Cost

Overmolding’s tooling is frequently more expensive due to two-shot design, precision alignment, and robust venting. However, it can reduce part count and eliminate adhesives or assembly, saving unit costs over volume. Insert molding spreads costs differently: the mold is simpler, but unit costs include the insert price and loading (manual or automated).

At low volumes, insert molding may reduce injection molding costs; at high volumes with strong consolidation benefits, overmolding can win on total cost of ownership.

Materials Used

Material strategy in overmolding centers on adhesion and shrink abilities. Overmolding pairs a substrate like ABS, PC, PP, or nylon with an overmold like TPE that must be compatible from both adhesion and processing standpoints. Insert molding commonly combines a thermoplastic—such as nylon with glass, PC, ABS, or PP—with metal inserts, magnets, or ceramics.

Techniques Used

Overmolding may be two-shot (rotating core/plate) or sequential (mold and re-mold). Surface preparation, texture, undercuts, and mechanical interlocks improve bond strength. Insert molding relies on precision insert placement, locating pins, and optimized designs built to flow plastic around the insert without voids.

Industries and Projects

Overmolding excels in consumer goods, medical industry disposables, handheld devices, and power tools where grip, sealing, and aesthetics are critical. Insert molding dominates in automotive industry parts like clips and brackets, industrial enclosures, medical device housings with threaded brass, aerospace connectors, and electronics where structural anchoring, threads, or conductive paths are required.

Design Complexity And Risk

With overmolding, the big risk is the two plastics not sticking well—because the resins don’t like each other, the surface was dirty, or the second shot ran too cool. Good design and early adhesion tests keep the bond from failing. With insert molding, the main risks are misplaced inserts, weak spots where flow splits around the insert, or cracks from different thermal expansion.

Quality And Reliability

For overmolded parts, the priority is bond strength—verifying that the soft layer remains firmly attached by measuring peel/adhesion and by running heat–cold cycles, moisture, and chemical exposure to check for lifting, cracking, or swelling. For insert-molded parts, the focus is insert retention—performing torque-out and pull-out tests to confirm inserts won’t loosen, and cycling temperatures so the plastic–metal interface tolerates expansion and contraction.

For both processes, early, structured trial runs help identify stable materials and machine settings, reducing variability before full production.

Other Factors to Consider When Choosing Overmolding vs Insert Molding

Choosing between overmolding vs insert molding starts with understanding your product goals and constraints. Use the following factors to frame a clear, side-by-side decision before committing to design and tooling.

Functional Requirements

If you need soft-touch grip, integrated sealing, or vibration damping, overmolding is the natural fit. If you need durable threads, load-bearing anchors, or embedded electronics, insert molding provides the mechanical or functional backbone your part requires.

Production Volume

With mass production injection molding for the high-volume needs of consumer products, overmolding can drive down total cost by eliminating secondary assembly. For moderate volumes or products with expensive precision inserts, insert molding may be more cost-predictable—especially if automated loading is feasible and scrap is tightly controlled.

Tolerance and Assembly Strategy

If downstream assembly relies on torque-capable features or precision alignment, insert molding with embedded metal threads or dowels improves repeatability. If the goal is to reduce assembly entirely, overmolding consolidates features into one operation.

Aesthetics and Branding

When the product’s look, feel, and brand accents are high priorities, overmolding enables textures, color breaks, and comfortable touch points. Insert molding is more hidden, improving the bones of the part rather than the surface experience.

Contact Our Injection Molding Experts For Your Project Today

Choosing the right injection molding approach can make or break product performance, cost, and timelines. Advanced Plastiform Inc. is a trusted resource by manufacturers across the Southeast and Mid-Atlantic, with the know-how to help businesses make confident, cost-smart choices between overmolding vs insert molding and other production decisions from concept to production.

We proudly serve clients across North Carolina, South Carolina, Pennsylvania, Maryland, Tennessee, Georgia, and Virginia—providing top-quality injection molded plastics you can rely on. To learn more and speak to a member of our team, call 919-404-2080 or fill out our contact form to get started.