Cooling Systems In Injection Molded Plastic Manufacturing

Cooling is the quiet workhorse of plastic injection molding—and often the biggest driver of cycle time and part cost.

For manufacturing custom plastic parts, an optimized mold cooling cycle improves dimensional stability, surface finish, and repeatability from shot to shot. Join our injection molding company as we explain how the cooling system works in the injection molding process for producing reliable custom plastics.

What Is a Cooling System in Injection Molding?

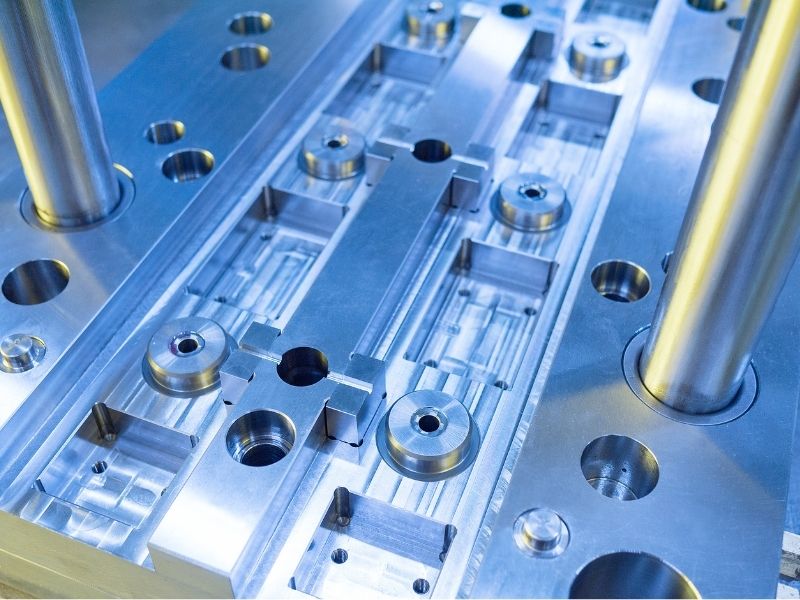

A cooling system is the network of channels, equipment, and controls that remove heat from the mold and newly formed plastic part after filling and packing the steel mold with the polymer material. Its job is to pull heat out fast and evenly so the plastic solidifies to the right dimensions and can be ejected without warp, sink, or surface defects. This is an extremely important step in the plastic injection molding process.

Key Cooling Components

Here are the core elements of a plastic injection molding cooling system—the parts that move, condition, and measure coolant to keep mold temperatures stable and manufacturing cycles efficient:

- Mold Cooling Channels: Drilled or conformal pathways inside the tool that carry coolant close to the part surface.

- Coolant: Usually conditioned water (sometimes water–glycol) circulated at set temperatures and flow rates.

- Manifolds, Hoses, Quick Disconnects: Route and balance flow to each circuit; enable fast mold changeovers.

- Temperature Control Units (TCUs): Maintain precise inlet temperature and flow; may use pressurized water for higher setpoints.

- Chillers/Central Cooling: Provide low-temperature coolant when needed and stabilize plant-wide heat load.

- Instrumentation: Flow meters, inlet/outlet temperature sensors, and pressure gauges to confirm turbulent flow and detect restrictions.

Where Cooling Happens: The Mold Cavity vs. Core

Effective mold cooling depends on where heat leaves the part—through the cavity side, the core side, or both. Each side sees different geometries, steel masses, and cosmetic demands, so the cooling strategy must match.

Cavity-Side Cooling

This is the side of the mold that gives the part its visible, aesthetic finish. The temperature has to stay very even to avoid dull spots, shiny streaks, or texture changes. Coolant channels are placed close to the mold surface—and sometimes shaped to follow the part—so heat is pulled out evenly without weakening the steel tooling of the machine.

Core-Side Cooling

The mold’s core is thicker and includes deep features like ribs, bosses, and tall pins that hold onto heat longer. To pull heat out of these hard-to-reach spots, molders use targeted tools—baffles and bubblers (to push water deeper), spiral/helical passages around cores, thermal pins (heat pipes), or high-conductivity inserts (often copper alloys). Balanced core cooling cuts warpage and helps parts release cleanly, keeping cycle times down.

How the Cooling System Works in the Molding Cycle

After the injection mold fills with molten plastic and the press applies pressure, the next—and usually longest—step is the plastic injection molding cooling process. During cooling, the plastic part solidifies enough to hold its shape and be ejected cleanly. If the mold opens too soon, you’ll see warp, sink, or parts that stick. In contrast, if it stays closed too long, injection molding costs and cycle time climb without quality gains.

The Simple Heat Path

Cooling is a heat hand-off where hot plastic touches the cooler mold, heat moves into the steel, and moving coolant (usually water) carries that heat away through internal channels. In plain terms, conduction moves heat from plastic to metal, and convection moves it from the metal to the flowing coolant.

The faster and more evenly this process happens, the sooner the custom plastic part is solid enough to eject without warping or sticking.

Why Coolant Flow Matters

Coolant needs to move fast enough to create turbulent flow—swirling, well-mixed water that scrubs heat off channel walls far better than a smooth, slow flow. Balanced manifolds and correctly sized hoses help every circuit get the same flow so no region of the mold runs hotter, which is a common source of warp and cosmetic defects.

What the Molder Controls

On the press, the molder dials in a few key settings. First is coolant temperature—cool enough to pull heat quickly, but matched to the resin and finish. Next, flow and pressure keep water moving fast through every circuit so no hot spots develop. Holding a steady mold temperature makes each shot during the plastic injection molding cycle cool the same way, and well-timed hold pressure feeds shrink before the gate freezes so the part keeps its shape.

When Is the New Plastic Part “Cool Enough”?

A part is ready to eject when both the surface and the inner core are solid and strong enough to hold shape during ejection. For amorphous plastics (like Acrylonitrile Butadiene Styrene), that means reaching a stable, glassy state. For semi-crystalline plastics (like Polypropylene), it also means giving the material time to form the right amount of crystals so shrink and stiffness are predictable.

The Payoff of a Successful Cooling Cycle

Well-designed, well-controlled cooling shortens cycle time, reduces internal stresses, improves surface finish, and delivers tighter, more predictable dimensions—shot after shot. In practice, that means higher throughput, less scrap, and fewer surprises during inspection.

Benefits of Cooling for Injection Molded Parts

Smart, well-balanced cooling is one of the fastest ways to improve part quality and productivity. By pulling heat out quickly and uniformly, you shorten cycles, stabilize dimensions, reduce defects, and lower plastic part cost.

Advantages of successful cooling include:

- Cycle time reduction and higher throughput

- Dimensional stability and tighter tolerances

- Less warp, sink, and residual stress

- Improved surface finish and cosmetics

- Lower scrap and rework

- Higher process capability

- Energy efficiency and better press utilization

- Longer tool life and simpler maintenance practices

- Better material performance

Contact Our Plastic Injection Molding Team Today

If you are ready to shorten production cycles and improve plastic part quality, contact Advanced Plastiform Inc. today. Our injection molding experts will review your CAD files and requirements, recommend the right cooling strategy, and provide a clear plan, pricing, and timeline so you can move from prototype to production with confidence.

We serve clients across North Carolina, South Carolina, Pennsylvania, Maryland, Tennessee, Georgia, and Virginia. Contact us today by calling 919-404-2080 or filling out our online contact form to get started.