When you need custom plastics manufactured, there are three options for production when using thermoplastics:…

4 Unbelievable Innovations in 3D Printing

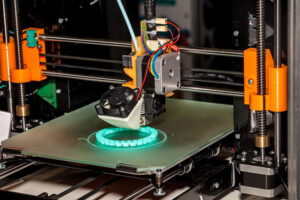

At our plastics manufacturing company, we use the latest technology to improve our clients’ experience and ensure we are designing and producing the best possible products. One of the ways we do this is by using 3D printing to create physical models from the 3D product design. This ensures our customers are satisfied with how the product will look in mass production, and then we can use the prototype to design molds and tools.

The field of 3D printing is opening up doors to all kinds of improvements in manufacturing, but both scientists and amateur enthusiasts are finding new uses for this technology. We wanted to highlight some of the most unbelievable innovations in 3D printing happening around the world.

3D Printing a Luxury Resort

The Kisawa Sanctuary Resort, located on Benguerra Island off Mozambique, is a 740-acre paradise that boasts 12 private bungalows, a meditation and yoga pavilion, and even a water sports area. The design is impressive, but what makes it truly amazing is that it is much of the building components will be 3D printed from a mortar made of sand and sea water!

By blending traditional building elements, such as thatching roofs, with highly sustainable materials, the designers hope to reduce the waste and emissions that are such a problem with most construction projects and create a sustainable method of building. The resort is scheduled to open in 2020.

3D Printed Steaks at the International Space Station

While Burger King made headlines with the Impossible® Whopper - a burger made from a plant-based protein patty. However, scientists at Aleph Farms have truly created seemingly impossible food by 3D bioprinting a real cow-based steak on the International Space Station.

What is bioprinting? It’s using 3D printing technology to incorporate living cells and has been used to produce tissue used in reconstructive surgery.

Aleph Farms’s first foray into 3D printing meat was in 2018, when they released “minute steaks” that were created in a lab and have only a three-week life cycle from cow muscle cells. As their goal is to make meat more sustainable and accessible, even in the most adverse conditions, they partnered with the Russian scientists on the ISS to bioprint thin, small pieces of steak. The zero-gravity environment allows the meat to print rapidly, without requiring a support structure of cells.

3D Printing Life-Size Anatomy Models Help Doctors in Canada

In Canada, physicians and surgeons are using 3D printing technology to create hearts, spines, and other organs, muscles, and bone structures to have an improved understanding of their patient before surgery. Instead of relying on 2D images from x-rays and CT scans, turning those images into a physical, life-size 3D model allows the physician to better treat their patients.

For example, if an implant is needed in the heart, having a 3D model gives the surgeon the ability to ensure the size and fit is accurate. Additionally, 3D printing anatomical models can improve training for nurses, ultrasound technicians, and other medical professionals.

Reconstructing Dinosaurs with 3D Printing

When dinosaur fossils are found, they are often in remote areas and are incredibly delicate. Shipping, studying, and displaying these bones can damage them, but by taking detailed images of the fossil, a 3D model of the bone can be printed instead. Additionally, using prints of bones or other fragile artifacts can allow museums to safely display accurate renditions and replicas without worrying that priceless items will be damaged. This opens the door to making museums more interactive and inclusive to all visitors!

The Naturalis Biodiversity Center reconstructed a full triceratops skeleton even though there were some pieces of the original skeleton missing. By scanning the available pieces, the team was able to identify the missing bones and print accurate replicas of the missing items. Meanwhile, at The Evolutionary Studies Institute in South Africa, they were able to use 3D printing technology to create a full massospondylus dinosaur skull using CT scans.

Contact Us for Your 3D Printing and Product Design Needs

While we don’t use 3D printing to create steaks, we do use it in our product design process to create prototypes that will allow us to better serve our customers. We work with customers throughout the Southeast and Mid-Atlantic, designing, manufacturing, and delivering custom plastics for a multitude of industries. To learn more, contact us today!

Contact Advanced Plastiform, Inc.

Let Us Know How We Can Help!